Comparative Analysis of Leading Manufacturing Execution System Software

By Lucy Chen | Published: 2025-03-21 | Category: Manufacturing Execution System Software

About Manufacturing Execution System Software

Manufacturing Execution System (MES) software provides real-time visibility and control over manufacturing operations, connecting plant floor activities with enterprise systems. It manages production processes from order release to finished goods, optimizing performance and ensuring quality.

Scoring Criteria

- → Functionality Breadth

- → Integration Capabilities

- → Scalability

- → User Interface & Ease of Use

- → Industry Specialization

- → Reporting & Analytics

The Best Manufacturing Execution System Software

Opcenter Execution

By Siemens

Comprehensive MES portfolio covering discrete, process, and electronics manufacturing, focusing on digitalization and Industry 4.0.

Platforms & Use Cases

Platforms: On-premise, Cloud, Hybrid

Best For: Discrete Manufacturing, Process Manufacturing, Electronics, Automotive, Aerospace & Defense

Key Features

- ✓Production Order Management: Manages the lifecycle of production orders.

- ✓Resource Allocation and Status: Tracks availability and status of machines, tools, and labor.

- ✓Quality Management: Integrates quality checks and non-conformance management within the production flow.

- ✓Process Data Collection: Captures real-time data from machines and operators.

- ✓Performance Analysis (OEE): Calculates and analyzes Overall Equipment Effectiveness.

Scorecard (Overall: 8.5 / 10.0)

Pricing

Enterprise

Contact Vendor

- Full suite access

- Custom implementation

- Support levels vary

Limitations: Requires significant investment and implementation effort

Pros

- + Extensive functionality

- + Strong integration with Siemens PLM/Automation

- + Highly scalable

- + Broad industry support

Cons

- - Can be complex to implement and manage

- - Higher cost compared to some competitors

Verdict

"A powerful, feature-rich MES for large enterprises, particularly those already invested in the Siemens ecosystem, seeking deep digitalization."

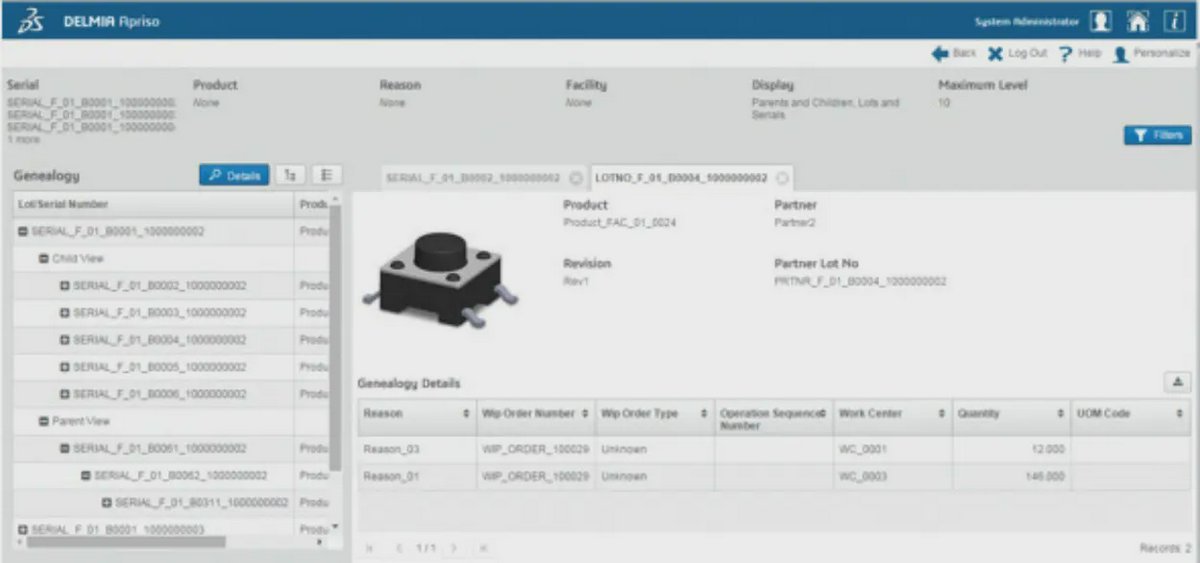

DELMIA Apriso

By Dassault Systèmes

Global manufacturing operations management platform synchronizing production, quality, warehouse, maintenance, and labor across the enterprise.

Platforms & Use Cases

Platforms: On-premise, Cloud, Hybrid

Best For: Complex Discrete Manufacturing, Automotive, Aerospace & Defense, Industrial Equipment, Consumer Packaged Goods

Key Features

- ✓Global Traceability: Provides end-to-end genealogy and traceability across multiple sites.

- ✓Business Process Management (BPM) Engine: Allows flexible modeling and orchestration of manufacturing processes.

- ✓Unified Data Model: Consolidates data from various manufacturing functions.

- ✓Quality Management: Enforces quality checks and manages deviations.

- ✓Manufacturing Intelligence: Delivers real-time analytics and dashboards for operational performance.

Scorecard (Overall: 8.2 / 10.0)

Pricing

Enterprise

Contact Vendor

- Modular approach

- Global deployment capabilities

- Extensive customization

Limitations: Complexity requires skilled implementation partners

Pros

- + Strong BPM capabilities for process flexibility

- + Excellent for multi-site operations

- + Comprehensive MOM scope beyond traditional MES

- + Integrates with Dassault Systèmes 3DEXPERIENCE platform

Cons

- - High implementation complexity and cost

- - User interface can be perceived as dated by some users

Verdict

"Ideal for large, global manufacturers needing a highly configurable and broad platform to manage complex, multi-site operations."

Proficy MES

By GE Digital

MES solution focused on improving operational efficiency, quality, and compliance, particularly strong in process and hybrid industries.

Platforms & Use Cases

Platforms: On-premise, Cloud, Hybrid

Best For: Process Manufacturing (Food & Bev, CPG), Hybrid Manufacturing, Discrete Manufacturing, Pharmaceuticals

Key Features

- ✓Production Execution & Tracking: Monitors and manages work orders and production progress.

- ✓Quality Management: In-line quality data collection and SPC.

- ✓Batch Management (Proficy Batch): Specific capabilities for batch process control and execution.

- ✓OEE & Performance Monitoring: Tracks equipment performance and downtime.

- ✓Genealogy & Traceability: Provides product history and tracking.

Scorecard (Overall: 8.0 / 10.0)

Pricing

Custom

Contact Vendor

- Modular deployment

- Integration with GE Predix platform

- Strong analytics capabilities

Limitations: Can require significant configuration

Pros

- + Strong focus on process and hybrid manufacturing

- + Robust batch management features

- + Good integration with automation layer

- + Leverages GE's industrial expertise

Cons

- - User interface could be more modern

- - Complexity varies depending on modules implemented

Verdict

"A solid choice for process and hybrid manufacturers, especially those needing strong batch management and integration with GE's broader industrial software portfolio."

FactoryTalk ProductionCentre

By Rockwell Automation

MES suite tightly integrated with Rockwell's automation and control systems, focusing on connectivity and performance.

Platforms & Use Cases

Platforms: On-premise

Best For: Discrete Manufacturing, Automotive, Life Sciences, CPG, Industries using Rockwell Automation controls

Key Features

- ✓Machine Integration: Seamless connectivity with Allen-Bradley PLCs and Rockwell Automation software.

- ✓Performance & OEE: Monitors asset utilization, performance, and downtime.

- ✓Quality Management: Integrates quality workflows and data collection.

- ✓Order Execution: Manages production schedules and work orders on the shop floor.

- ✓Track & Trace: Provides product genealogy and traceability.

Scorecard (Overall: 7.8 / 10.0)

Pricing

Suite/Modular

Contact Vendor

- Deep integration with Rockwell ecosystem

- Scalable architecture

- Industry-specific application suites

Limitations: Primarily on-premise focused, Best suited for environments heavy on Rockwell Automation hardware

Pros

- + Unmatched integration with Rockwell Automation systems

- + Strong focus on shop floor connectivity

- + Comprehensive suite of MES applications

- + Good support for regulated industries

Cons

- - Less platform flexibility (primarily on-premise)

- - Can be perceived as complex

- - Value maximized in Rockwell-centric environments

Verdict

"The go-to MES for manufacturers heavily invested in the Rockwell Automation ecosystem, offering deep integration and control."

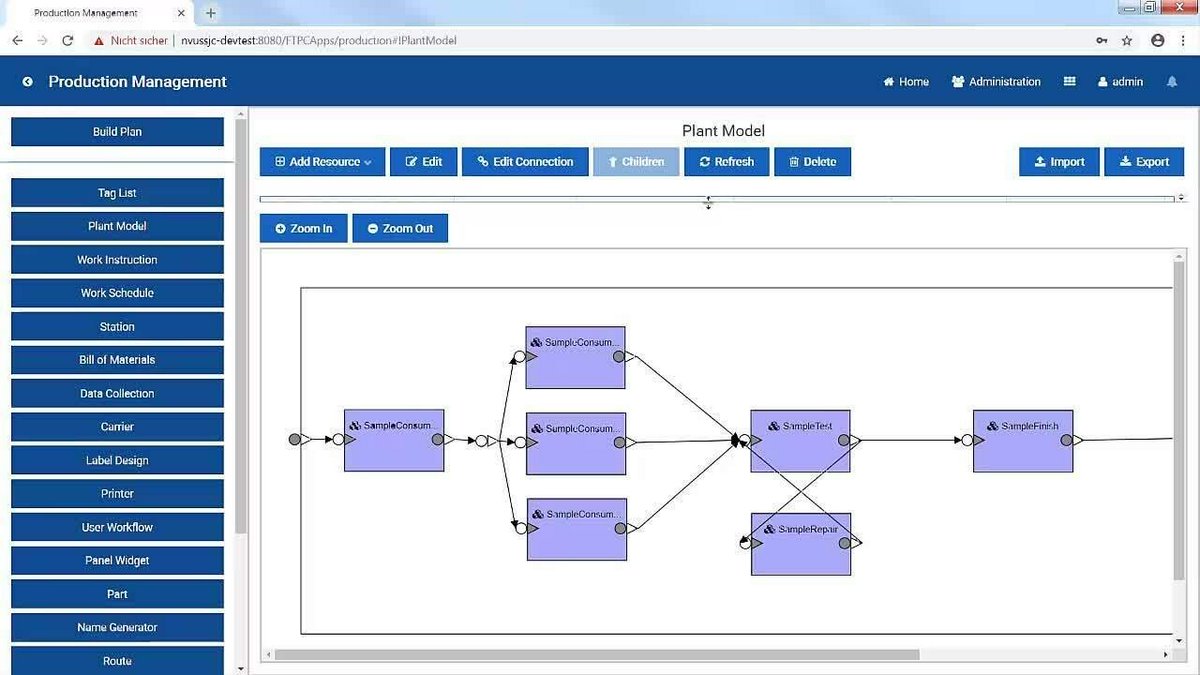

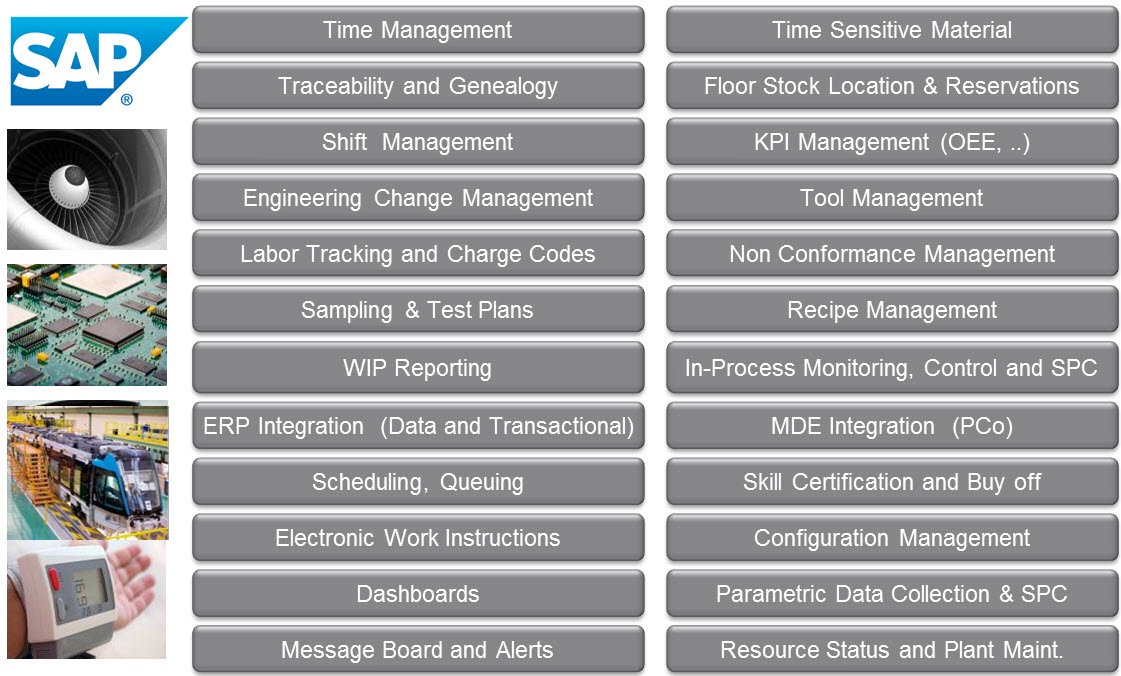

SAP Manufacturing Execution

By SAP

MES solution designed for tight integration with SAP ERP (S/4HANA), managing and monitoring work orders and production activities.

Platforms & Use Cases

Platforms: On-premise, Cloud (SAP Digital Manufacturing Cloud)

Best For: Discrete Manufacturing, Process Manufacturing, Companies using SAP ERP, Automotive, Mill Products

Key Features

- ✓ERP Integration: Seamless data flow between shop floor and SAP ERP systems.

- ✓Production Execution: Guides operators through production steps and captures data.

- ✓Labor Tracking: Monitors labor time and activities.

- ✓Nonconformance Management: Handles defect tracking and resolution processes.

- ✓Performance Analytics: Provides insights into production KPIs.

Scorecard (Overall: 8.0 / 10.0)

Pricing

Enterprise

Contact Vendor

- Native integration with SAP S/4HANA

- Cloud and on-premise options

- Leverages SAP ecosystem

Limitations: Complexity associated with SAP environments, Can be expensive

Pros

- + Best-in-class integration with SAP ERP

- + Robust feature set for execution and monitoring

- + Strong scalability for large enterprises

- + Growing cloud capabilities (SAP DMC)

Cons

- - Implementation can be complex and costly

- - Value heavily tied to use of SAP ERP

- - UI improvements ongoing

Verdict

"The default choice for large organizations running SAP ERP, providing seamless integration and comprehensive manufacturing execution capabilities."

Plex Smart Manufacturing Platform

By Rockwell Automation (formerly Plex Systems)

Cloud-native manufacturing platform offering MES, ERP, and Quality Management (QMS) capabilities, primarily for discrete and process manufacturers.

Platforms & Use Cases

Platforms: Cloud

Best For: Automotive, Food & Beverage, Industrial Manufacturing, Plastics & Rubber, Metal Fabrication

Key Features

- ✓Cloud-Native Architecture: Built for the cloud, offering scalability and accessibility.

- ✓Integrated ERP/MES/QMS: Provides a unified platform for core manufacturing operations.

- ✓Production Monitoring: Real-time tracking of jobs, inventory, and machine status.

- ✓Inventory Management: Manages raw materials, WIP, and finished goods.

- ✓Quality Management: Includes SPC, checklists, and nonconformance tracking.

Scorecard (Overall: 8.0 / 10.0)

Pricing

Subscription

Contact Vendor

- Multi-tenant cloud

- Regular updates

- Integrated suite

Limitations: Less customizable than some on-premise giants, Primarily cloud-based deployment

Pros

- + True multi-tenant cloud platform

- + Integrated ERP, MES, and QMS reduces complexity

- + Strong in specific verticals like Automotive and Food & Bev

- + Modern user interface

Cons

- - Integration with non-Plex systems requires APIs/connectors

- - Acquisition by Rockwell may shift focus

Verdict

"A leading cloud-native option, particularly strong for manufacturers seeking an integrated ERP/MES/QMS solution without extensive on-premise infrastructure."

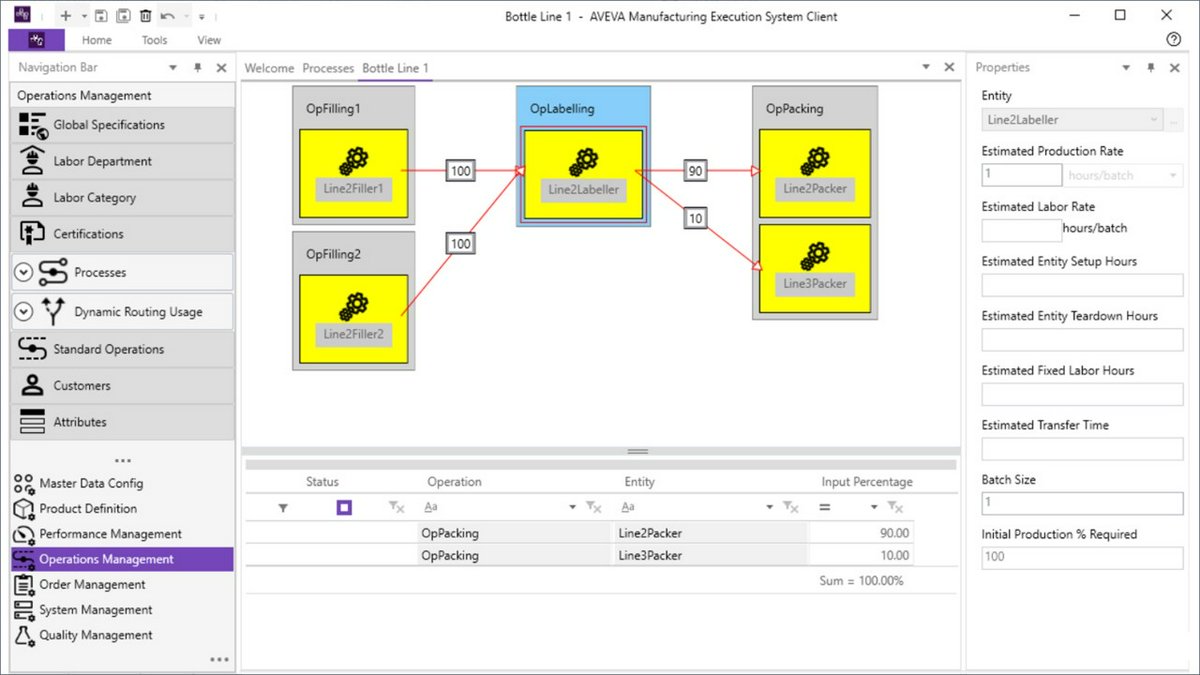

AVEVA Manufacturing Execution System

By AVEVA

Scalable MES solution (formerly Wonderware) providing operations management, performance monitoring, and quality capabilities across various industries.

Platforms & Use Cases

Platforms: On-premise, Hybrid

Best For: Process Manufacturing (Food & Bev, CPG), Hybrid Manufacturing, Infrastructure, Discrete Manufacturing

Key Features

- ✓Workflow Management: Digitizes SOPs and guides operators through tasks.

- ✓Performance Management: Tracks OEE, downtime, and production counts.

- ✓Quality Management: Integrated sampling, SPC, and defect tracking.

- ✓Inventory Tracking: Manages WIP and material consumption.

- ✓Batch Management: Model-driven batch execution capabilities.

Scorecard (Overall: 7.8 / 10.0)

Pricing

Modular

Contact Vendor

- Strong integration with AVEVA portfolio (System Platform, Historian)

- Model-driven approach

- Scalability from single site to enterprise

Limitations: User interface modernization is ongoing, Can be complex depending on modules

Pros

- + Strong legacy and install base (Wonderware)

- + Good integration with AVEVA's industrial software suite

- + Model-driven approach aids standardization

- + Scalable solution

Cons

- - Interface may feel less modern than some competitors

- - Requires expertise for optimal configuration

Verdict

"A robust and scalable MES, especially valuable for companies utilizing other AVEVA industrial software products, with strengths in process and hybrid manufacturing."

Epicor MES (Advanced MES)

By Epicor

MES solution (formerly Mattec) focused on real-time production monitoring, OEE, and machine connectivity, often integrated with Epicor ERP.

Platforms & Use Cases

Platforms: On-premise, Cloud

Best For: Discrete Manufacturing, Metal Fabrication, Plastics, Rubber, Users of Epicor ERP

Key Features

- ✓Real-Time Production Monitoring: Tracks machine status, cycle times, and output automatically.

- ✓OEE & Analytics: Calculates and analyzes OEE, downtime reasons, and scrap.

- ✓Machine Connectivity: Direct interface with PLCs and machine controls.

- ✓Scheduling Visualization: Provides visibility into job progress against schedule.

- ✓Quality Management: Captures quality data and manages rejects.

Scorecard (Overall: 7.5 / 10.0)

Pricing

Module

Contact Vendor

- Strong machine connectivity

- Focus on OEE and shop floor visibility

- Integration with Epicor Kinetic (ERP)

Limitations: Functionality may be less broad than top-tier enterprise MES, UI design could be updated

Pros

- + Excellent machine monitoring and OEE capabilities

- + Strong integration with Epicor ERP

- + Good for discrete manufacturing focused on efficiency

- + Real-time data focus

Cons

- - User interface is functional but less modern

- - Scope might be narrower than platforms like Siemens or Dassault

Verdict

"A strong contender for discrete manufacturers focused on machine performance and OEE, particularly those already using or considering Epicor ERP."

DELMIAworks (IQMS)

By Dassault Systèmes

Integrated ERP and MES system specifically designed for small to mid-sized repetitive manufacturers.

Platforms & Use Cases

Platforms: On-premise, Cloud

Best For: Plastics Manufacturing, Medical Device, Automotive Tier 2/3, Assembly, Metal Stamping

Key Features

- ✓Integrated ERP/MES: Single database for manufacturing and business operations.

- ✓RealTime Production Monitoring: Direct machine connection for status and process data.

- ✓Scheduling & Planning: Finite capacity scheduling tools.

- ✓Quality Management: Built-in QMS features for compliance and control.

- ✓Inventory & Warehouse Management: Tracks materials from receiving to shipping.

Scorecard (Overall: 7.5 / 10.0)

Pricing

Suite

Contact Vendor

- Single-source solution for ERP & MES

- Strong in specific manufacturing niches

- Real-time process monitoring focus

Limitations: Less flexible than modular enterprise systems, Primarily targets SMB manufacturers

Pros

- + Tight integration between ERP and MES functions

- + Strong focus and feature set for specific manufacturing types (e.g., plastics)

- + Easier implementation for SMBs compared to large enterprise systems

- + Good real-time monitoring

Cons

- - Less suited for very large, complex, or highly diverse manufacturers

- - Integration outside its own ecosystem less emphasized

Verdict

"An excellent choice for small-to-medium sized manufacturers, especially in plastics, automotive supply, and medical devices, seeking a single, integrated ERP/MES solution."

FactoryLogix

By Aegis Software

MES platform focused on complex discrete manufacturing, particularly strong in electronics assembly (SMT), aerospace, and medical devices.

Platforms & Use Cases

Platforms: On-premise, Cloud

Best For: Electronics Manufacturing (SMT), Aerospace & Defense, Medical Devices, Complex Discrete Assembly

Key Features

- ✓NPI & Process Engineering: Tools for rapid new product introduction and process planning directly from CAD/BOM data.

- ✓Lean Material Management: Just-in-time material handling, verification, and traceability.

- ✓Adaptive Process Control: Real-time adjustments based on collected data.

- ✓Quality & Nonconformance: Integrated quality data collection, analysis, and failure reporting.

- ✓Traceability & Genealogy: Detailed tracking for high-compliance industries.

Scorecard (Overall: 8.2 / 10.0)

Pricing

Modular

Contact Vendor

- Deep functionality for electronics assembly

- Strong NPI capabilities

- Focus on IIoT and machine connectivity

Limitations: Less known outside its core industries

Pros

- + Leading MES for electronics manufacturing

- + Excellent NPI and process engineering tools

- + Strong traceability and quality features

- + Modern architecture and interface

Cons

- - Market presence concentrated in specific verticals

- - May be overkill for simpler manufacturing processes

Verdict

"A top-tier MES solution for complex discrete manufacturing, particularly unmatched in the electronics assembly space, also serving A&D and medical device sectors well."

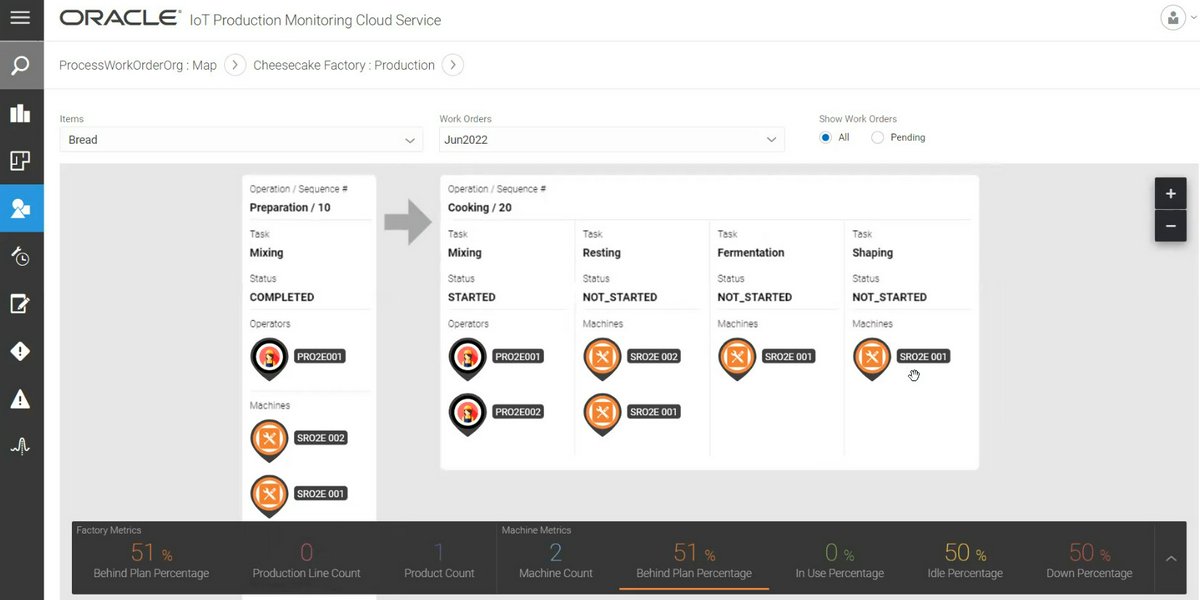

Oracle Manufacturing Cloud

By Oracle

Cloud-based solution within Oracle's SCM Cloud suite offering integrated MES, IoT, AI, and supply chain capabilities.

Platforms & Use Cases

Platforms: Cloud

Best For: Discrete Manufacturing, Process Manufacturing, Mixed-mode Manufacturing, Organizations using Oracle Cloud ecosystem

Key Features

- ✓Integrated SCM & ERP: Seamless connection with Oracle's broader Cloud application suite.

- ✓Production Execution: Dispatch lists, work order management, operator UIs.

- ✓IoT Production Monitoring: Leverages IoT Cloud for real-time machine data and insights.

- ✓Quality Management Integration: Connects with Oracle Quality Management Cloud.

- ✓Supply Chain Collaboration: Extends visibility across the supply chain.

Scorecard (Overall: 8.0 / 10.0)

Pricing

Subscription

Contact Vendor

- Cloud-native

- Integrated with Oracle Cloud apps

- AI/ML capabilities emerging

- Scalable cloud infrastructure

Limitations: Best value within the Oracle Cloud ecosystem, Relatively newer MES focus compared to specialized vendors

Pros

- + Strong integration within Oracle SCM/ERP Cloud

- + Leverages modern cloud technologies (IoT, AI)

- + Scalable and accessible via cloud

- + Unified user experience across Oracle Cloud apps

Cons

- - MES feature depth may still be evolving compared to dedicated MES leaders

- - Primarily beneficial for companies committed to Oracle Cloud

Verdict

"A compelling cloud option for manufacturers already invested in or moving to the Oracle Cloud ecosystem, offering seamless integration and leveraging advanced technologies."

Final Thoughts

The MES software market offers diverse solutions, from comprehensive enterprise platforms by Siemens, Dassault Systèmes, and SAP, often tightly integrated with their respective ecosystems, to specialized systems like Aegis FactoryLogix for electronics, and cloud-native platforms like Plex. GE Digital and AVEVA provide strong options, particularly for process industries, while Rockwell Automation excels in environments using its control systems. Epicor MES and DELMIAworks cater well to mid-market discrete manufacturers, and Oracle provides a strong cloud-integrated offering.